Part 1: Aug 21, 2012

and

Part 2: Aug 28, 2012

Join the "CWTD Yahoo Group" for

email discussion in between our weekly sessions by clicking

here.

Troubleshooting Techniques!

Basic guidance on troubleshooting

circuits that should be working ... but are not.

Overview

So you've spent five hours building up a circuit board,

carefully following every instruction and suggested tip, and you've powered it

up and ... [ARRGGGHHHHH] ... NOTHING! That darned thing

doesn't work at all! Just how do you go about trying to fix it?

The session this week presents some basic guidance and and

methodology to help when building up circuits initially and trying to get them

working. And we have a good "case example" of a circuit that we'll go

through from a troubleshooting guidance perspective ... and maybe you'll get

some ideas for those other projects on your bench needing some TLC.

73, George N2APB & Joe N2CX

Audio Recording

(for Part 1 on Aug 21)

... (Listen

to the MP3 podcast)

Audio Recording (for Part 2 on Aug 28)

... (Listen

to the MP3 podcast)

Part 1 (Aug 21) Discussion

Notes:

<20:08:41> "Joe N2CX":

http://inventors.about.com/od/bstartinventors/a/John_Backus_2.htm

<20:09:41> "Terry WB4JFI": Good timing! I'm in the middle of building an

Ensemble RX II right now - in the middle of the filters construction

<20:12:03> "Joe N2CX": "regular" solder is often .036 or .062 for toooobs

<20:14:40> "Al K8AXW": Radio Shack has Solderwick

<20:15:40> "Charles WC5MC": scanning your PCB with a scanner before you start

building/adding parts is good to have to refer to ex. prebuildpcb.jpg

<20:16:55> "Paul - wa0rse": @Charles: That's a great idea. Scanner or even a

macro photo is good during build and debugging!

<20:17:57> "Paul - wa0rse": Stereo microscopes are really good! The ones with a

"boom" rather than a typical microscope stage would be my next purchase if I saw

one!

<20:18:36> "John ZL1AZS":

http://www.microscope.com/microscopes/stereo/

<20:20:13> "Joe N2CX": JOhn, thanks for the link. It's going on my "to purchase"

list!

<20:20:57> "Paul - wa0rse": Something like this:

http://www.microscope.com/omano-om2300s-jw11-zoom-stereo-boom-microscope.html

is what I meant by a "boom microscope".

<20:22:14> "Terry WB4JFI": softrock

www.wb5rvz.com . I'm using it for the first time. It's great

<20:22:21> "Joe N2CX":

http://www.wb5rvz.com/sdr/ensemble_rx_ii/

<20:22:55> "John ZL1AZS": All their mics come with a foam cut padded aluminium

"flight" case

<20:23:55> "Pete - WB2QLL": also nice to download data sheets for the chips and

other special parts

<20:24:18> "Joe N2CX": Retrovo.com often has oddball manuals for consumer

and computer stuff

<20:25:02> "Al - N8WQ": I also use my ipad 3 to view the pdf while building

<20:26:18> "Mike - WA8BXN": for the many that don't have a scope or signal

generator, a working transceiver can be very helpful to listen for oscillators

and provide a signal (into a dummy load)

<20:27:03> "Pete - WB2QLL": General coverage receiver is useful too!

<20:28:34> "Pete - WB2QLL": IR thermometers useful to see if transistors are

working/balanced, other parts heating

<20:29:30> "Larry - W2HHV": Use ESR meter to check electrolytic/tantalum caps in

circuit.

<20:29:47> "Joe N2CX":

http://dl.dropbox.com/u/43021514/CWTD/Aug%2021.html

<20:29:51> "Al - N8WQ": 4.4x loupe (spelling not sure)

<20:30:40> "K4UPG-Kelly": I use my antenna analyzer as a signal source.

<20:44:29> "George - N2APB": Indeed, an antenna analyzer is a great signal

source. MFJ-259, Micro908, RF Analyst, etc.

<20:44:48> "Paul - wa0rse": Probing the *pin* and not the *pad* of an IC detects

bad solder joints more reliably, Joe/George

<20:44:58> "George - N2APB": I just LOVE, however, the Elecraft XG-3 for this

purpose. LOVE IT!

<20:50:17> "K4UPG-Kelly": handy tip!

<20:54:40> "Charles WC5MC": There will be the default freq

<20:58:57> "Terry WB4JFI": Si570 tool: cfgsr, a link to it is in WB5RVZ's notes

<21:09:12> "Terry WB4JFI": pulling parts from working TV set designs: Mad

ManMuntz

<21:13:33> "Terry WB4JFI": The screw holes themselves appear to be isolated. If

you use the nylon washer under the one screw near the USB, you should be OK.

<21:14:25> "Al K8AXW": What about shielding of the digital circuitry??

<21:14:56> "VA3KMD - Ken": If you want to open a real can of worms, do a topic

on sorting out ground loops.

<21:20:10> "John ZL1AZS":

https://sites.google.com/site/g4zfqradio/softrock_ensemble_isolation_transformers

<21:20:57> "K4UPG-Kelly": Tnx fer gud tips and clear presentation of techniques.

Most helpful for a novice tweaker like me!

<21:21:11> "Bryan AA3WM": Thanks George and everyone else. I wish I could be

here more often.

<21:21:15> "Paul - wa0rse": Oh, my! Ground loops! Biophysical research

laboratories have been known to run 2 different grounds. One, "reference ground"

may only sink or source microamps worth of current from each "jack" in the lab.

The other, "dumping ground", is used to accept current from power supplies. They

come together at the ground rod but can be tested for the current running

through them.

<21:21:36> "Joe N2CX": John, thanks for the link!

<21:22:21> "Paul - wa0rse": This is done to isolate any IR drop noise due to

changing power current from sensitive, high gain grounds.

<21:24:09> "VA3KMD - Ken": Paul: and then there's all those square metres of

patient skin picking up all the broad spectrum noise.

Part 2 (Aug 28) Discussion

Notes:

<20:07:30> "George - N2APB": Joe, mention the good

reflector discussion concerning benefits of using a stereo microscope, or even a

camera!

<20:18:07> "Joe N2CX": U3 is the Si570

<20:26:30> "Pete - WB2QLL": An explanation of "quadrature" in this context might

be helpful for some.

<20:30:18> "Pete - WB2QLL": "commutating mixer" = "switching mixer"

<20:35:11> "Alan W2AEW": Here's my video on 10x probe compensation:

http://www.youtube.com/watch?v=SX4HGNWBe5M

<20:35:45> "Alan W2AEW": ...and my video on scope triggering:

http://www.youtube.com/watch?v=OFGm-Pel4Hg

<20:36:03> "Joe N2CX": Good helpful videos indeed!

<20:36:19> "John ZL1AZS": A question about software oscilloscopes for later

please

<20:36:29> "Alan W2AEW": ...and one on AC/DC coupling:

http://www.youtube.com/watch?v=Hkq-fvb5-NI

<20:40:38> "Joe N2CX": Digital scopes are an invention of the devil - at least

for those of us learned to use a friendly unambiguous analog scope...

<20:51:49> "Joe N2CX":

https://sites.google.com/site/g4zfqradio/softrock_ensemble_isolation_transformers

for the transformer wiring corrections

<21:01:30> "Ken - VA3KMD": Aren't the T3 outputs 180 degs out of phase?

<21:01:46> "Joe N2CX": Yes, good catch!

<21:03:33> "Ken - VA3KMD": So U11 is just a class B amplifier.

<21:03:57> "Alan W2AEW": class A actually (I believe)

<21:04:30> "Joe N2CX": No, the two sections are Class A linear amps with equal

gains and some high frequency filtering.

<21:04:58> "Ken - VA3KMD": The non-inverting inputs are biased at 2.5V.

<21:06:09> "Alan W2AEW": Maybe you covered this before I came in - but what is

the IQ bandwidth of this RX? ...or, is it purely limited by the sound card's BW

<21:09:05> "George - N2APB": The I & Q audio BW is usually limted by the

coupling capacitors from the op amps. Generally, you want to keep the BW within

that of the sound card.

<21:09:07> "Alan W2AEW": You can measure the phase shift easily by putting them

into Ch1 and Ch2 of a scope, and put the scope in XY mode. Resulting lissajous

pattern should be circular

<21:09:19> "Alan W2AEW": tnx George

<21:11:53> "Ken - VA3KMD": Joe: you're right.

<21:12:10> "John ZL1AZS":

http://groups.yahoo.com/group/softrock40/

<21:15:28> "Pete - WB2QLL": Tony's current web page for SoftRock devices:

http://www.fivedash.com/

<21:23:19> "Alan W2AEW": whew- glad you said that - makes me feel better about

the pile of test equipment in my shop!

<21:24:22> "Alan W2AEW": ...and a good background of IQ signals - I had to do

this for my colleagues too

<21:24:52> "Alan W2AEW": I=in phase, Q = quadrature (90 out of phase)

<21:27:20> "John ZL1AZS": Not too long in the future all this stuff will be on

one chip!

<21:27:28> "Bryan AA3WM": Thanks George and Joe!

<21:27:42> "Ray K2ULR": 73

SESSION NOTES

Are we

"troubleshooting" or "debugging"?

Troubleshooting and debugging really are related though

they are really two distinct aspects of the same thing. They involve testing a

circuit or piece of equipment that doesn't perform as expected.

In my mind the difference

between the two activities comes from whether or not the object of your

attention ever worked in the first place. If it did at one time, then you are

troubleshooting. If it never did you are debugging. A couple of examples can

help show the difference.

Let's say you have been using

a commercial transceiver for several years and notice one day that it is not

transmitting. The steps you take to find out why it is no longer working is

troubleshooting. You can have pretty good confidence when you find the problem

and fix it that the item will once again work as expected. This is what a

service tech or auto mechanic does to fix something brought to them for repair.

On the other hand if you

build a "from scratch" homebrew project or kit and it doesn't work, what you do

to find out why and fix the problem is debugging. Debugging involves a lot more

head scratching to first of all determine whether or not you know just how well

the equipment should work, figuring out why it doesn't, then correcting the

problem. Along the way you just may find that it never will actually work the

way you first expected - particularly if the equipment design is shaky in the

first place.

So in summary, debugging is

what you do to a piece of gear that has never worked and troubleshooting is what

you to restore equipment to its previous state of correct operation. Naturally

there are gray areas between these two distinctions, but I think you get the

idea.

Tools

- Needle nose pliers,

side cutters, .015" solder, soldering iron, hot air (removal) X-Tronix

4000 is a great one,

- Magnified

visors and good light

- Long standoffs - Put

on both sides of the pc board so you can have the board elevated above the table

surface. Enables you to probe the circuits

- Camera - blow up the

image to see it on a monitor. Good for documenting construction stages

along the way too.

- 3rd Hand - Something

to hold a circuit board to hold in the air so you can probe on the top and

bottom

- Solder braid - pretty

useful to clean up solder splashes, shorts, removal of ICs, etc.

- Stereo Microscope -

Similar to use of the camera, it's a very good technique to help if you are

visually impaired.

Information

- Kit schematics -

printout and have available on the bench for physical use (marking, notes)

during construction on the bench

- Errata - make sure you

have all the latest changes and fixes

- User Group dialog -

Other people might have already shared their insight and tips.

- Instructions, block diagram, theory of operation, errata, other people's

comments, email forum postings?

- Leave the manual

pristine, but photocopy the pages so you can mark off the steps as you proceed,

without mucking up things permanently.

- WB5RVZ has a great

website with super good info on building the Softrock, as well as guidance for

building up the project in stages

- Google is Your Friend

- In addition to getting all related information about a project,

technology or tool. Try also using some advanced search techniques,

specifying PDF or other desired results

- Check out your

suppliers and get some of their manuals

Equipment

- DVM, RF Probe - The

obvious, low cost tools we have can be used quite effectively for a lot of the

basics

- Oscilloscope -- It's

really helpful to be able to actually see the signal - even a DC level - in

order to determine other characteristics that a DVM might not. Is there

noise on the DC level? What is the nature of the noise? Is it

pulsing, HF, UHF, superimposed pulse train, etc .. Everything is a clue when

hunting down the elusive causes for a non-functional circuit.

- Signal Generator/Source

- My favorite little piece of equipment is a signal injector that you can use to

squirt a signal into the RF front end. Just love my Elecraft XG-3 signal

source.

- Speaker -- Can be

helpful to hear if your circuit is alive, hear scratches or hum ... all useful

- Mating equipment ...

Computer sound card

- Antenna -- perhaps

obvious, but having a live antenna feeding down to your workbench can be a real

plus. Allows you to get some real-life signals into your circuit so you

can do some tracing. Think of the value in being able to tune a

receiver-under-test to WWV and having a nice, regular signals being pumped along

the signal path!

- Golden Original - A

working model of what you're working on in order to do an A/B comparison can be

invaluable for determining the right voltages or circuit behavior

- Your Finger! -- An old

trick is to stick your finger in a high gain circuit to inject a little hum or

even RF signals that might help you see circuit activity

- General Techniques

- Use the scope to look

at signals to see if

- Check to see if the

power is on! Sometimes the obvious answer is the hardest one to find

- Current Draw? -- Is

the current being pulled from your DC supply in the right ballpark? Too

little indicates possible open circuits, missing power leads to ICs, etc.

Too much indicates a possible short circuit or a component that's inserted

backwards. Good to have a metered power supply for these techniques, of

course.

- Battery power -- If

you were to be using batteries as your DC power source during initial

troubleshooting, you might be able to save some of the circuits in the event of

shorted or polarity-reversed conditions because your battery terminal voltage

usually will drop if the unusual/problematic current demand of your circuit is

too much. (If you have a nice stiff power supply - one that can supply

lots of current - such a condition could well supply the multiple amps being

requested of a shorted circuit, thus more easily producing smoke from your

components. And another nice touch, perhaps if you don't have batteries on

hand to use in powering unknown circuits, is to use a power supply that can be

current limited; so by setting your power supply never to exceed sourcing 200ma

(for example), you'll have a better chance of protecting your circuits when

there is miswiring.

- Signals generally

present? -- Sometimes you can very quickly get a feeling for the circuit

operational status just by doing a quick probe around the board with a scope.

If there are wiggling signals present, pulse trains, or evidence of oscillations

(where there should be some), you'll have a better feeling for being able to get

the circuit working in shorter order. If, however, no signals are to be

found anywhere on the board, and unexpected/wrong DC levels in key areas (like

on the output of a voltage regulator), you know that something larger is at play

and perhaps needing more careful attention "upstream".

Divide-and-Conquer

- You usually

know when a circuit does not work when there is no sound coming out of the

speaker, or when the LCD display has nothing on it, or when the XYZ behavior is

not happening. You could start at the main input or start of the signal

chain and follow things through to where you lose the signal. or you could

start at the end and work backwards until you encounter the stage where the

signal finally disappears. But perhaps a quicker and more sensible way to

go about locating the fault is by looking halfway back to start with.

Then if it the signal is present there, then the problem bust be in the

second half of the circuit. If it signal is not present at the halfway

point then you know the problem is in the first half of the overall

schematic. Then do this again (go forward or back halfway from that point

to the start or end of the circuit and ask the same questions This "divide

and conquer" approach helps you zoom in on the problematic stage of the circuit

real efficiently with the minimum of headaches. Once you've found the

errant stage, then you can pull out the heavy artillery to actually diagnose the

problem.

Proper Components on

the board?

- This one falls into

the DUH! category, and it is a check that is so often overlooked. First,

don't assume that every part in you kit, or that every one pulled from your

1K-ohm parts bin is actually 1k ohms. perhaps you grabbed from the wrong

bin, or perhaps the vendor mislabeled the part (it does happen!!), such a

condition can easily mess up your circuit operation and yet go unnoticed for the

longest time.

Proper Orientation?

- Pin 1 or pin 14? --

Make sure that the IC's in your circuit are all properly inserted/attached to

the board. Double check where pin 1 is on the device (dot on the case, upper end

of the beveled side of the plastic body, etc). Make sure you know the pin

numbering for those special ICs with 5 pins (in the SOT-23 case, for example) an

where the numbering starts and works itself around.

- Anode or cathode --

Such an easy thing to determine, but often the source of circuit malfunction.

The cathode side of the component (and electrical symbol) is marked by a band,

or a straight line. "Toward the bar" is the direction the current flows in

a diode. Be sure to match the bar on the body of the diode with the bar

symbol typically on the silkscreen layout of the pc board.

Triple-check your

soldering!

- Soldering the legs of

an IC to the pads - Can't say enough about the need for good solder connections

on a component or IC. Things to watch out for include: solder shorts

between leads (use solder braid to suck up excess solder), not enough solder

and/or a raised IC lead that results in the IC leg hovering over the pad but not

making electrical connection. This is a tough one to see from direct

top-down approach ... turn the board at different angles while looking at the

solder junction under high magnification. Another trick is to carefully -

ever so carefully - probe the actual lead of the IC (not the soldered junction)

to determine if the proper signal is actually reaching the IC.

- Missed solder

connections -- Sometimes when in a hurry, you might skip over an IC lead and

miss making the solder connection for it. This obviously can cause

problems with signal continuity through a stage, as the electrical connection is

completely missing! A good practice to follow is to lightly retouch each

solder connection with a little thin solder to ensure that you didn't miss any

leads.

- Cold solder joints --

Learn to solder properly and do it often! There are many good online

references and videos for doing this.

Getting the dang

computer & sound card set up

Oftentimes the hardest

part of getting a Softrock working is getting things set up right on your

computer.

- Is yours fast enough?

A computer that is too slow or burdened with too much data already on its hard

drive will appear sluggish and no responsive ... just when you want it to be be

snappy. Always try to use the fastest computer you can get when using one

for SDR applications, as these programs can get pretty big and bloated,

requiring lots of disk space and memory to work optimally.

- Stereo or mono inputs?

Be careful about this one. Quadrature-sampling SDR radios generate and

require stereo sound card interface - one channel for the In-Phase (i) signal,

and another for the quadrature (q) signal. So if your older laptop's mic

jack only has a mono input capability, then you won't be able to properly decode

the SDR signals. The best solution, in general (because even newer laptops

still only have mono inputs) is to use an external USB sound card like that from

Creative Labs (Sound blaster equivalent). Often just $25 or so, this will

serve you well with stereo input capability, as well as (usually) a higher input

sampling rate, which will produce better SDR operation.

- Win7 supported?

(Or how to get WinXP again?) -- Sometimes an SDR application works okay on Win

XP, but not on Win 7. Or perhaps the driver for the sound card or Si570

chip isn't working properly on Win 7. If this is the case, you could try

running Win XP from a Virtual Machine on your Win 7 computer. Thus the SDR

application thinks it's running happily along in XP. I use Virtual Box as

the virtual machine program on my Win 7 computer - it's free and easy to use ...

just need to get an image of the XP operating system (like from your older

computer?) and load it within Virtual Box.

Selecting the PC

application

- Rocky, WinRad, WinHD,

HDSDR -- Rocky is quite good, but for some reason I seem to have problems

running it on Win 7. I have the best luck using WinHD (now called HDSDR).

- Get the CFGSDR utility

(see the WB5RVZ website) so you can first just run the Si570 clock chip on your

Ensemble board like a simple LO. Once you know the clock chip is working

okay, then you can bring up the SDR program (WinHD) to actually try decoding

some on-the-air signals.

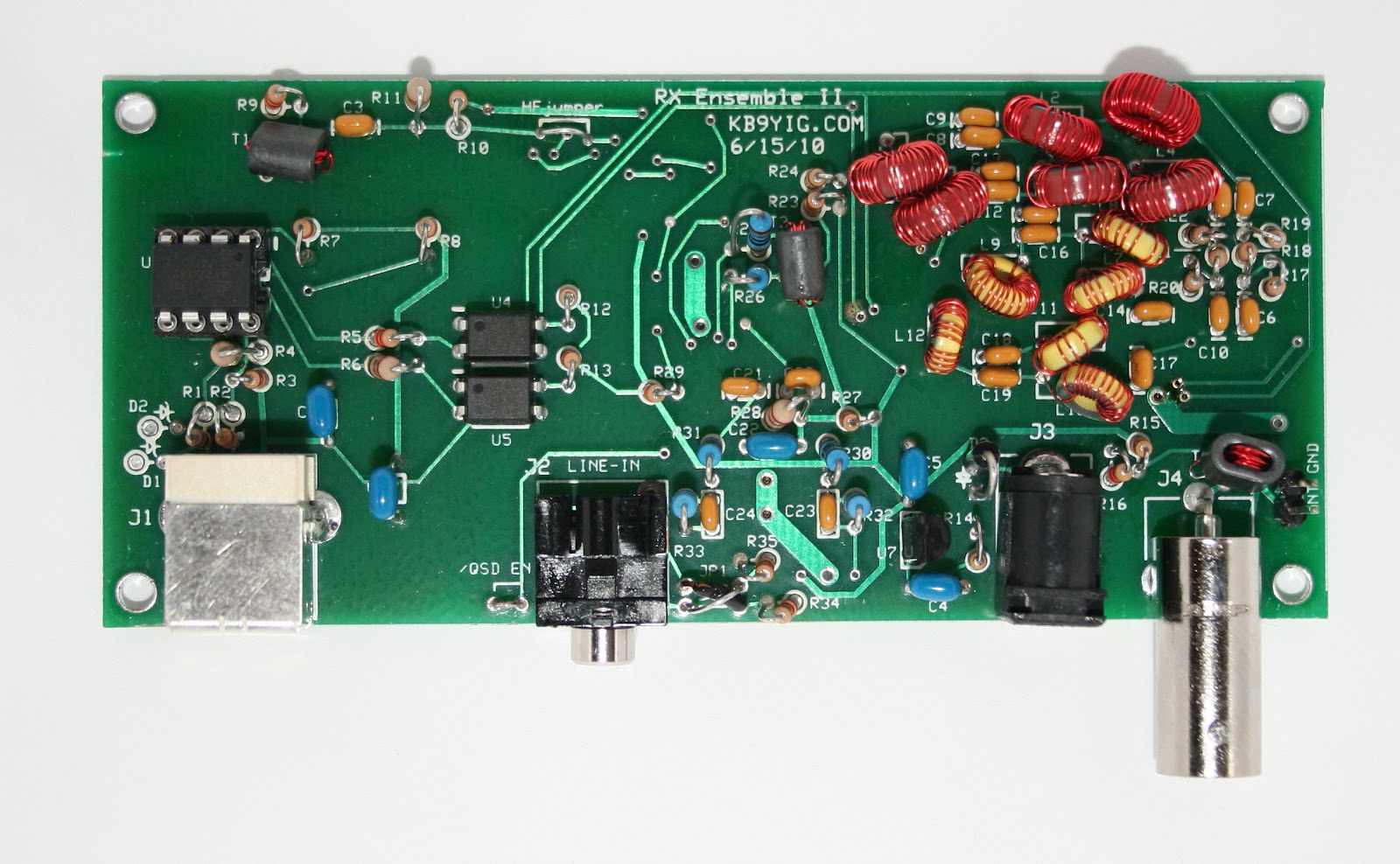

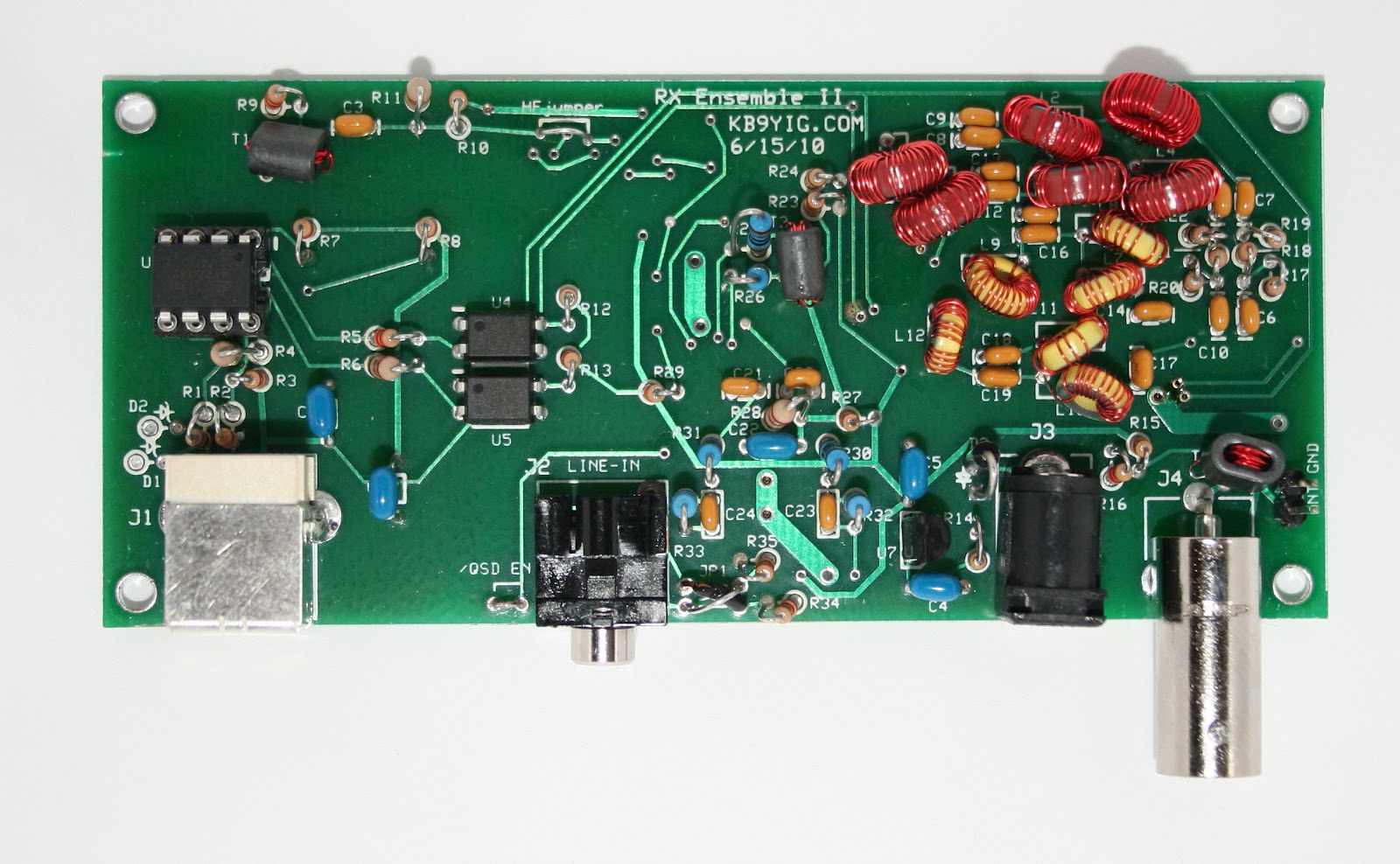

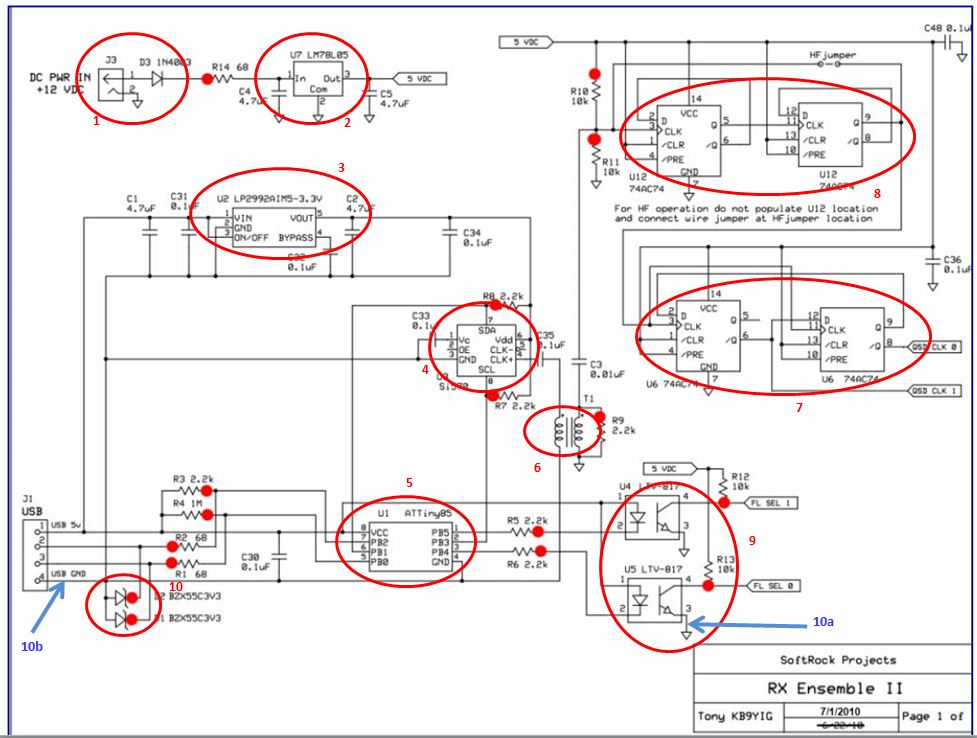

Click images for larger view

Nothing better

than a real-life project to go through and debug together! The

Softrock Ensemble II Receiver is a great collection of many principles

and circuit components that we've been studying over the last several

months, and we'll go through the two-page schematic in a top-down manner

that will perhaps give you some insight on how to either fix your own

Ensemble (there are a bunch of these in the NJQRP needing attention), or

an approach for you to repair other QRP kits you may have sitting on the

shelf.

And by the way, the

Ensemble RX II Kit is once again available!

Visit ...

http://fivedash.com/index.php?main_page=product_info&cPath=1&products_id=6&zenid=bb16ec0fbbc93a4c09ebf3f683356aa7

THEORY OF OPERATION

... To understand how the Ensemble Rx II receiver works, you can read the

great description on the

WB5RVZ website, which also happens to have all the details for building and

testing the project. Great for learning more about the circuits we're

going to discuss this evening!

"GENTLEMEN, START

YOUR ENGINES!"

So lets get into it!

The red ovals in the schematics are numbered and we'll discuss them in fairly sequential order. Generally, they represent the functional blocks of

the circuit ...

Bubble 1: Power connector and polarity protection diode. This

is obviously a good place to start troubleshooting - the Ensemble needs 12V

power to work! If the diode is in backwards, you'll see 12V on the

jack-side of the diode, but nothing on the right side.

Bubble 2: 5V regulator provides clean and regulated 5V power to

most of the circuits on the Ensemble ... except for the ICs in bubbles 3, 4

and 5. To measure the 5V output of U7, you must gave the ground probe of

your scope/DVM on the larger ground plane on the right side of the board.

(More about this later.) If you don't measure 5V on the output of

U7, then perhaps the regulator isn't soldering in correctly, or perhaps

something else along the 5V bus is pulling it down. Use the "Divide and

Conquer" approach for finding what might be at fault with the 5V bus. If

you still can't find a problem along the bus, then try raising just the output

leg of U7 to see if it works with no load on its output.

Bubble 3: 3.3V regulator provides clean and regulated 3.3V to the

USB and clock generator components on the left side of the board. Note:

When measuring the output of U2, be sure that your ground lead of the scope/DVM

is indeed on the smaller ground of the left side of the board. The input side of

the voltage regulator U2 should be about 5V, as fed by the 5V pin on the USB

connector. Note: You must have the USB cable plugged into a live

computer for the Ensemble clock circuits to work. If the cable is not

there, 5V is not provided to U2 and there will be no 3.3V to run the Si570 chip.

Also note the filter capacitors on the inputs and outputs of both regulators U2

and U7. These caps help keep the regulated buses clean of high frequency

oscillations and filter out any noise.

Bubble 5: U1 is an ATTiny05 microcontroller chip pre-programmed to

interface to the protocols coming from the computer USB port . This is how

the SDR programs running on the computer instruct the Si570 clock generator to

generate sp[ecific frequencies as the LO for the Ensemble receiver. The

USB data lines coming in to U1 pins 5 and 7 serially command U1 pins 2 and 6 to

move in an manner to as to program the Si570 to generate a specific frequency.

Most often these SDA and SCL lines aer quiescent (not moving), but when the user

adjusts the VFO on the radio interface displayed on the computer, these lines

wiggle like crazy and you can see the new frequency on the output pin of the

Si570. It is easiest to see this LO frequency (which by the way is at 4

times the frequency you are operating ... e.g., the popular 7040 kHz position on

your 40m dial requires the Si570 to be generating 4 x 7040 kHz, or 28.160 MHz.

So if you are using a scope to check the output of the Si570 chip, be sure it

has sufficient BW to see such a fast signal. Generally, a scope spec'd

with a "50 MHz Bandwidth" or more should be able to see this just fine.

Bubble 6: Transformer T1 is used to couple the Si570 clock signal from

the digital/USB side of the board (with the smaller ground plane) over to the RF

signal handling side of the board on the right. It is probably much easier

to place your scope probe on the transformer secondary, at the top of resistor

R9 at the top edge of the board. Remember to place the scope's ground lead

on the larger ground plane on the right side of the board!

Bubble 9: Opto isolators U4 and U5 also serve to couple some

signals over to the right side of the board - this time it's the two Frequency

Select signals Fsel1 and Fsel2 coming from the ATTiny controller. The

controller's software determines what frequency is being generated by the Si570

and it uses its output bits PB4 and PB5 as bandswitching controls to the filter

switching happening on the right side of the board. These bandswitching

controls can be easily tested by changing the VFO dial setting of the radio

interface on the computer to be on a different band while monitoring Fsel1 and

Fsel2. Again, be sure to have the ground lead of your scope or DVM on the

right-side ground while measuring the two signals at R12 and R13.

Bubble 10: These two Shottky diodes merely serve to protect the

inputs of the ATTiny controller chip from going too high (in the event that

these USB data lines have wild spikes or noise coming in over the cable.)

Arrows 10a and 10b: These arrows serve to remind us that there are two

completely separate grounds on the Ensemble Receiver ... the smaller one on the

left side serving the USB and clock generation; and the larger ground on the

right side serving all the RF processing circuitry. A logical question is:

"Should I ever connect these two grounds at some point?" It would be a

good practice to connect the right-side RF processing ground to the enclosure

containing the receiver. But we should keep the digital/USB ground on the

left side isolated from the chassis (and hence from the RF processing side of

the board) so as to not introduce any unwanted digital USB or clock signals into

the RF processing. Simply stated, the USB and clock ground stays connected

to the computer, and the RF processing ground gets connected to the antenna.